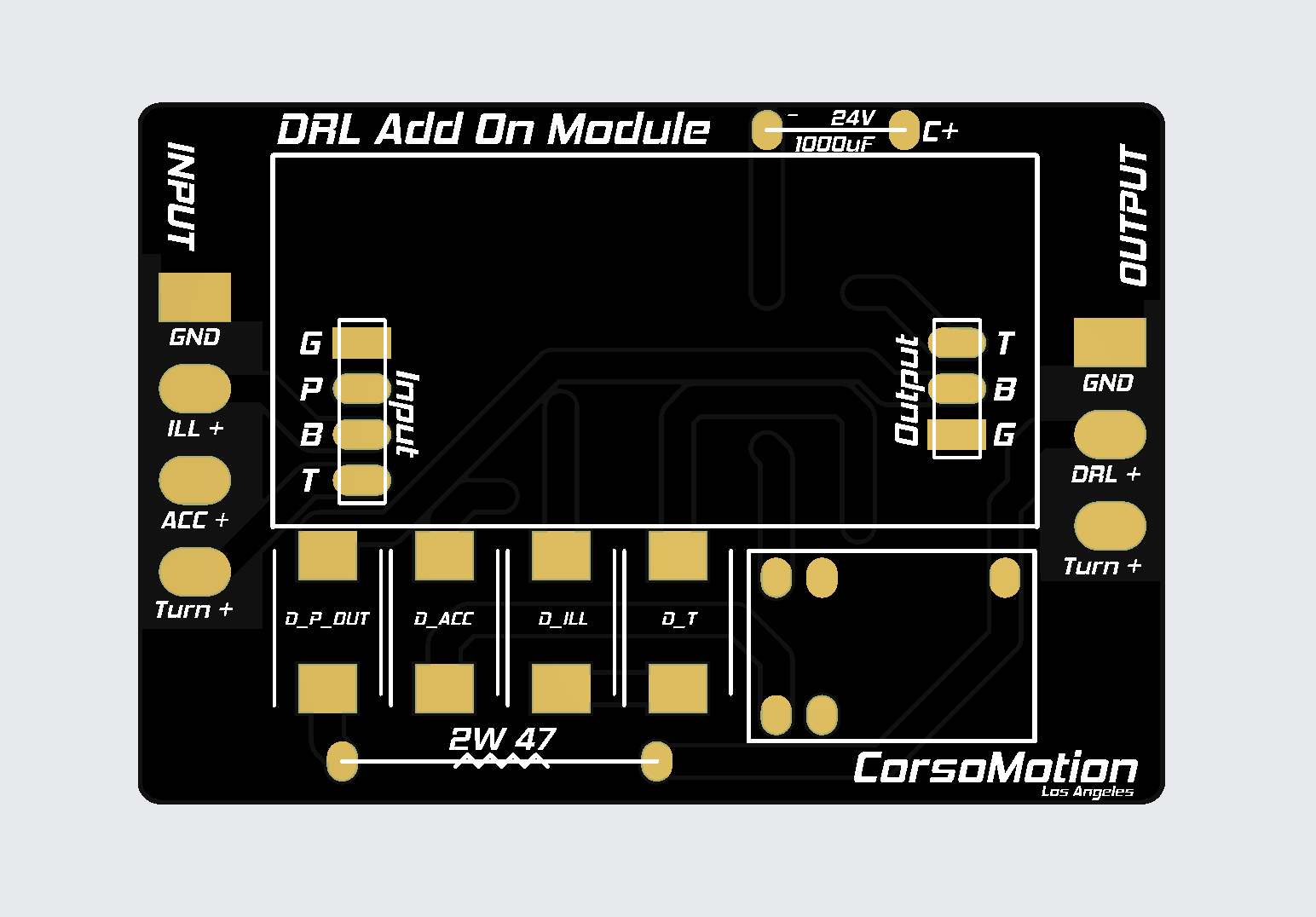

DRL Add on Module with switchback modules | pair

This DRL add-on module has completed development and will be released soon, so the photos and description video have not been updated yet. However, it is available for order now and will be ready for shipping shortly. This DRL add-on module is designed to dim the brightness of the white LEDs when the headlights or parking lights are turned on (depending on the user’s settings). This add-on module comes with our Switchback Module Classic version pre-installed. https://corsomotion.com/products/led-switchback-control-modules-ver-2-for-2-color-led-setup-pair?_pos=1&_psq=switchback&_ss=e&_v=1.0 If you are connecting it to a Sequencer module or a different version of the module, you should order the DRL Add-On Module LITE version, which does not include the Switchback Module Classic. The input terminals include Turn signal+, ILL+, ACC+, and GND. The primary function of this add-on module is to adjust the brightness of the white LED connected to the headlights when the vehicle is started and when the headlights or parking lights are turned on. The wiring method varies depending on how the input wires are connected. For example, if the user connects a wire from Engine ON+ to ACC+ (such as from the fuse box) and a wire from headlight ON+ to ILL+, the white LED connected to the headlights will light up at 100% brightness when the engine is turned on. Then, when the headlights are turned on, the white LEDs will dim automatically. Reference InformationWhen you search for a DRL module, you’ll find two versions: the DRL Add-On Module Lite and the DRL Add-On Module with Switchback Module. The DRL Add-On Module Lite is designed to be installed as an add-on to the input terminals of our Sequencer Module or Switchback Flash Control Module. The DRL Add-On Module with Switchback Module differs from the Lite version in that it comes with our Switchback Module Classic pre-installed on the DRL Add-On Module board. There are two types of Switchback Modules: the Switchback Flash Control Module and the Switchback Module Classic. The Switchback Flash Control Module is our latest model, featuring DIP switches that allow you to select various functions. (common positive system) The Switchback Module Classic, on the other hand, is more compact but lacks the additional functions provided by the DIP switches. (common ground system) Another key difference is that the Switchback Flash Control Module controls LEDs using a common positive system, while the Switchback Module Classic controls LEDs using a common ground system. If you have any questions, please contact us at contact@corsomotion.com. Thank you. Custom Made Boards Custom Made Board [7x2] 2P Bi-Color, Lens ver. 600x600mil Custom Made Board [7x4] 2P Bi-Color, Lens ver. 600x600mil Custom Made Board [7x6] 2P Bi-Color, Lens ver. 600x600mil The ones below don't need the LENSes Custom Made Board [7x2] 4P Bi-Color, Plain ver. 600x600mil Custom Made Board [7x4] 4P Bi-Color, Plain ver. 600x600mil Custom Made Board [7x6] 4P Bi-Color, Plain ver. 600x600mil Bi-Color LED Strips Bi-Color LED Strip, 4P x 19Ch, 15000x350mil Side Support Panels Support Panel Type-A Support Panel Type-B Modules Sequential LED control module ver.1.10, for 1 color LED setup Sequential LED control module ver.2.00, for 2 color LED setup Pre-Cut wires Pre-cut wire BLACK 22AWG 7.8inch/20cm Pre-cut wire WHITE 22AWG 7.8inch/20cm Pre-cut wire RED 22AWG 7.8inch/20cm Pre-cut wire YELLOW 22AWG 7.8inch/20cm Etc. 15 Pin Female header 30 Pin Female header 40 Pin Male to Male wire 20cm Advantages of Using the Common Positive System in Automotive LED Lighting In automotive LED lighting, the common positive system is widely used due to its numerous advantages. Here are some key reasons why this method is preferred: 🔹 1. Simplified Wiring and Reduced Costs In a common positive system, the vehicle chassis (metal body) serves as the ground (negative connection) for all electrical components. This reduces the need for additional negative wires, simplifying the wiring structure and lowering production and installation costs. It also minimizes wiring complexity, making it easier to maintain and troubleshoot. 🔹 2. Increased Reliability and Stability Since all components share a stable positive voltage source, voltage fluctuations are minimized, ensuring consistent LED brightness and performance. The chassis ground provides a low-resistance path, improving overall electrical efficiency and reducing the risk of connection failures. 🔹 3. Compatibility with Automotive Electrical Systems Most automotive electrical systems, including headlights, brake lights, and turn signals, use common positive wiring to maintain standardization across different components. This allows seamless integration of additional LED modules or aftermarket lighting without requiring major modifications to the vehicle's electrical system. 🔹 4. Better Protection Against Electrical Faults In case of a short circuit, the negative (ground) side is affected rather than the power supply, reducing the risk of damaging the entire system. This design helps protect LEDs and other electronic components from sudden voltage spikes and electrical failures. 🔹 5. Easier Integration with Control Modules Many LED controllers and dimmers used in automotive applications are designed to work with common positive configurations. This makes it easier to integrate RGB LED strips, DRLs (Daytime Running Lights), and other lighting systems without additional circuit modifications. Conclusion The common positive system in automotive LED lighting offers simplified wiring, improved reliability, compatibility with vehicle electrical systems, better fault protection, and easier integration with controllers. These advantages make it the preferred choice for manufacturers and aftermarket installers, ensuring efficient and stable LED lighting performance.